Adoption View

Vision & Mission

Introduction

The German Supply Chain Due Diligence Act came into force on 1 January 2023. This law regulates corporate responsibility for compliance with human rights in global supply chains. These include, for example, protection against child labour, the right to fair wages and the protection of the environment. This legislation can be added to a long list of existing and future legislations that regulate our global supply chains, like the EU Corporate Sustainability Due Diligence Directive (CSDDD), the EU Ecodesign for Sustainable Products Regulation (ESPR), EU Corporate Sustainability Reporting Directive (CRSD), the International Bill of Human Rights, the UN Guiding Principles on Business and Human Rights, the OECD Guidelines for Multinational Enterprises, as well as the ILO core labour standards and the principles of the UN Global Compact.

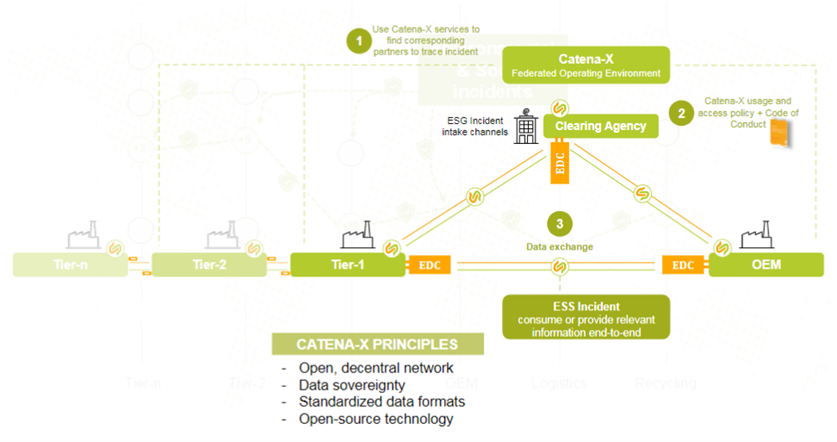

Catena-X aims to support supply chain due diligence obligations in a market environment that misses full up- and downstream transparency. This is argued to be relevant for Environmental and Social Standards (ESS) incident tracking, without compromising GAIA-X and Catena-X principles like data sovereignty, interoperability, standardization, and use of federated services.

The ESS-solution enables companies to search for ESS incidents in their supply chain and thus covers the "occasion-related tracking of ESS-related incidents" for the Supply Chain Act. Basically there are two search directions: The bottom - up search starts at the Incident Originator and works downstream up to the OEM. The top - down search always looks towards the direct suppliers and works upstream.

Vision

As companies governed by environment and social standards (ESS), we would like to determine, if we are affected by an incident reported in the global supply network. Consequently, we could prove to be fully compliant with legal requirements, including but not limited to the German Supply Chain Due Diligence Act.

Mission

The automotive supply network is described as highly complex and globally interwoven. It operates in a heterogeneous political and environmental context with many different ambitions. The current challenges for cross-company ESS incident management are described by:

- High manual effort of a small set of experts that work in their own silos and focus on company-centric investigation. A problem accentuated at the level of small and medium enterprises (SME),

- Low network collaboration and by that long processing time amongst business partners,

- Lack of trust to share data, amongst many intermediates,

- Varying quality of information and sources.

Our mission is to streamline the handling of incidents reported to the Catena-X network. The ESS KIT supports cross-company ESS incident management with appropriate processes. This radical change from our organization-centred model would mitigate the challenges listed above. The ESS KIT consists of the following building blocks:

- Standards to guarantee data sovereignty and data security, like the Connector KIT (EDC), Business Partner KIT and Agents KIT, as well as our standards,

- Standardized data model accompanied with a defined tracing process to reduce processing time for an incident.

Business value

If Catena-X members want to minimize their ESS risk and bring transparency into their supply chains, there is a strong need to collect knowledge and reliable information. Arguably, the primary added value of the ESS KIT is our simplified cross-company communication coupled with the Clearing Agency concept.

With the Clearing Agency in place, business partners subscribing to the ESS KIT, can with confidence collect incidents from multiple actors and a broad range of sources (e.g. receiving incidents from company's internal incident management systems or from public news reports and automated information gathering). The Clearing Agency, as an independent body will among other activities reduce fraudulent cases and consolidate information of potential incidents.

The processes of the ESS KIT will transfer information in the respective supply chains to efficiently zero-in on the relevant business partners. So, with the ESS KIT, the members of the Catena-X network are enabled to act quickly due to collaboration and standardization.

Furthermore, the ESS KIT allows for quick adaptation to new national and internal laws and helps ensure legal compliance through enhanced supply chain transparency and verification.

Thus, the ESS incident KIT offers a uniform and cross-sectoral grievance mechanism for managing incidents related to specific occasions, filling a gap that currently exists.

Use Case

Prerequisites

The scope of our business is the prompt handling of incidents reported to the Catena-X network. The following prerequisites are necessary for the ESS KIT:

- High number of Catena-X members need to be onboarded to cover our supply chains and increase the success rate of the tracing of incidents,

- Catena-X members agree to a Code of Conduct,

- The member needs to follow the onboarding process.

Customer Journey: Occasion-related tracking of ESS-related incidents

This customer journey describes the process when an incident is reported to the Catena-X network. From the determination that needs to be made regarding its relevance to the business partners and further processing.

This KIT support the detection of incidents from different sources (manual or automated), before being categorized by incident types / sub-types. The unstructured information (text and/or pictures) about each incident will be collected along with country-, company-, material-related data if available (note: no BoM data collected). The quality of the incident data is not guaranteed at this stage and for some cases, the investigation may be challenging due to insufficient information about the supply network.

The Clearing Agency is prompted to clear incidents. This independent body has the tasks among others, to improve quality of data and reduce fraud or fakes. This includes but is not limited to, manual search and input from expert, consolidation of reports of the same incident and finally accept or archive incidents. Once the Clearing Agency found that the incident's originator is a Catena-X member, the Clearing Agency can use Catena-X Services find out the BPN-L, BPN-S and the EDC endpoints of the incident originator. We assume that a unique ESS incident ID will be provided. Then the ESS incident is transferred to the incident originator via the Catena-X network. In case no Catena-X member can be identified as incident originator or L0, the Clearing Agency will maintain the corresponding status "no member found". If no Catena-X member can be identified, from a Catena-X network perspective, this supply chain is broken or incomplete. This is described in the chapter about Occasion-related tracking in broken supply chains, see below.

The investigation of the ESS-related incident is used to determine the cause of the reported incident. All business partners involved work to identify and confirm the origin of the incident. Once the source is identified and confirmed, a decision is made by the business partners whether to accept or reject the ESS-related incident.

The trace of an incident is operated through the decentral Catena-X supply network. The process moves from business partner to business partner in their supply chain with the incident originator as the starting point for a bottom - up approach and at the OEM for a top - down approach.

The use case ESS believes that the most promising way to solve an ESS incident will be a bottom - up approach. This is described here.

It means that the transfer of information is initiated by the L0 who identifies its impacted customers (L1) using the bottom-up search logic (for example Knowledge Agent). The impacted customers (L1) can then push the information down the supply chain (i.e. their impacted customers or L2) and so on until it arrives at the end of the chain (i.e. OEM).

The trace of an incident follows previously mentioned principles along any obligations enforced by law. For any business partner in the supply chain, its access to the status/information related to a specific incident will depend on its degree of relationship with the impacted company:

Level 0 (L~0~): the incident report is targeting the company directly. At that level, the incident manager of the L~0~ can consult all the relevant information and will manage the status and response.

Level 1 (L~1~): those business partners have a direct relationship with the L~0~. As already supported in existing legislations, L~1~ business partners will have access to the status of the incident and the full information of the potential incident at the L~0~.

Level n (L~n~): those business partners have an indirect relationship with the potential incident originator (L~0~). They will receive from the previous business partner (L~n-1~) the anonymized incident information (anonymized title & description, category, status, etc.) along with the degree of relationship (i.e. their distance to the L~0~). The incident originator's identity (L~0~) and the path from L~0~ to L~n~ in the impacted supply chain will not be communicated, nor documented.

Clearing Agency: these users can see the status and the original intake of information of all incidents. The Clearing Agency will only be able to identify the targeted business partner (L~0~) who is handling the incident. Finally, if the incident can be closed by the L0, the Clearing Agency will receive a status update.

Note: For the top - down approach with IRS recursive this is not applicable because no information about the ESS incident is transferred between Business Partners. See Data Chain KIT for further details.

Note: There is an explanatory video published on youtube. ESS video

Customer Journey: Occasion-related tracking in broken supply chains

If no Catena-X member can be identified within the Catena-X network, other external sources could be used to identify the missing suppliers and fill the gaps that are relevant for this ESS incident.

For each supplier that could be found, the Clearing Agency would need to check against the Catena-X network if a BPN is available or not. The identified supplier (there could be more than one), who is a member of the Catena-X network, will be assigned as the ESS incident moderator for this ESS incident. The incident moderator can be addressed via the EDC endpoint of the Business Partner and is most likely the incident manager of this Business Partner. Now, the tracing of an ESS incident can continue as described above. The ESS incident moderator shall trace the supply chain both upstream (towards his suppliers) and downstream (towards his customers). For Business Partners, that are members of the supply chain, the Catena-X network and its services can be utilized, for Business Partners, that are not in the Catena-X network other means of communication must be used.

ESS Incidents personas

Incident Issuer

| Short Description | Task / Responsibilities |

|---|---|

| Issuer can be any person or institution | Raise ESS-related incident in a structured or unstructured manner |

| Not necessarily an ESS expert | Ambition to make ESS-related issue transparent and visible with as much information as possible |

| Can be either internal (e.g. auditor or employee) or external (e.g. business partner, individual, NGO, automatic-detection) | Committed to provide relevant information to properly address the ESS-related incident to the right business partner/ organizational unit |

| Uses either formal contact point (Catena-X Incident App, Catena-X Webpage, Company Webpage) or any kind of (social) media to issue ESS-related incident | |

| Potential contact to incident manager (ESS), human rights officer/risk management specialist |

Incident Manager

| Short Description | Task / Responsibilities |

|---|---|

| Operational internal role/ central function that covers incidents as primary responsibility | Recording of ESS-related incidents |

| Follows statutory requirements and incidents through each process step until closure | Assignment of the ESS-related incident to the correct category with as much information as possible. Categories are: Violation of environmental and/or social standards |

| First contact and dispatcher for ESS-related incidents and incident status | Rejection or acceptance of ESS-related incident |

| Incident-Manager to get in contact with (e.g. sustainability@...) | Assignment of ESS-incident to internal business partner |

| SME/Business Partner for human rights officer, sustainability manager product/corporate, audit (internal, external) | Collaboration & cooperation with business partners and internal units |

| Potential contact to incident issuer (ESS) | Agreement of binding measures with relevant SMEs/ Business Partners |

Clearing Agent

| Short Description | Task / Responsibilities |

|---|---|

| Operational internal role/ central function that covers incidents as primary responsibility | Receives incident from various sources |

| First contact and dispatcher for ESS-related incidents and incident status | Reduce fraud / identify fake incidents |

| Consolidate incidents (no multiples) | |

| Set / maintain central incident status and anonymized information (respectively one-up/one-down, decentral, data-sovereign, "flag" to allow sharing) | |

| Forward information to L0 of cleared ESS incident or archive of ESS incident | |

| Transfer ESS incidents to archive |

Semantic models

Catena-X offers various semantic models depending on the specific application and KIT. They establish a fundamental understanding of the data and its connections, facilitating compatibility between different data sets. The data models of Catena-X prioritize principles such as clarity, standardization, distinction, verifiability, and comprehensiveness.

The data model follows the Catena-X Standard CX-0144 and is modelled following the Standard CX-0003. Below, you can find an excerpt of the full data set:

ESS Incident Information

| Attribute Name | Description | Example |

|---|---|---|

| Category and sub-category | Environmental and social standards related incident category according to Supply Chain Due Diligence Act | Environmental (e.g., usage of mercury, usage of harmful chemicals) | Social (e.g., child labour, work safety, discrimination) |

| Subject and description | Title of an incident in the context of ESS (Environmental and Social Standards) with its description | Child labour in country x for product y reported. Small children under the age of 15 clean barrels with bare hands and under dubious working and payment conditions. |

| Attachment(s) | Picture(s) about the reported incident in the context of ESS (Environmental and Social Standards) | Upload picture about child work in country x for product y or upload other additional documents/reports |

| Date | Date and time information when an incident occurred | 2022-08-31T00:00:00Z |

Product Information

| Attribute Name | Description | Example |

|---|---|---|

| Description | Description of product or component affected by an incident in the context of ESS (Environmental and Social Standards) | Natural Rubber |

| Raw material | Raw material that causes an incident in the context of ESS (Environmental and Social Standards) | Mercury | Cobalt | Natural Rubber |

Company Information

| Attribute Name | Description | Example |

|---|---|---|

| Country subdivision | Region within a country to which an incident in the context of ESS (Environmental and Social Standards) belongs | Sao Paolo |

| Coordinates | Exact geographic position of an incident in the context of ESS (Environmental and Social Standards) | Longitude and Latitude (will be entered automatically) |

| Company name | Name of a company / an organisation that is the originator of an incident in the context of ESS (Environmental and Social Standards) | ABC company |

| Address | Address of ESS originator (street, zip code, city...) | Mainroad 1, 73230 Model City |

| BpnL / BpnS / BpnA | BPN-L/S/A of the company that causes the incident | Rubbery Ltd. (BPN-L: BPNL1234567890ZZ) | Site in Dingolfing (BPN-S) | Dingolfing Werksstrasse 1, Tor 2.1 (BPN-A) |

Contact Information

| Attribute Name | Description | Example |

|---|---|---|

| First and last Name | Contact name of ESS incident issuer | Camille Mustermensch |

| E-Mail Address | E-Mail address of ESS incident issuer | xyz.abc@xxx.com |

| Phone number | Phone number of ESS incident issuer | +49 89 123456789 |

| Address | Address of ESS incident issuer | XYZ-Road, 73230 Kirchheim |

| Anonymous | Flag that Incident issuer wants to be anonymous | Checkbox: ticked / not ticked |

Business process

Business architecture

Access & Usage Policies / Code of Conduct

Code of Conduct of the Catena-X Use Case Sustainability / Environmental and Social standards

In the Catena-X use case sustainability / environmental and social standards, principles are established with the aim of establishing transparent and trustworthy practices within the Catena-X network. The Code of Conduct will be published on the Catena-X webpage

Standards

List of standards

To participate in the ESS Incident Management use-case, the following single standards must be fulfilled and can be consulted in the Catena-X Standard Library:

- CX-0001 EDC Discovery API

- CX-0006 Registration and initial on Boarding

- CX-0013 Identity of Member Companies

- CX-0014 Employees and Technical Users

- CX-0015 IAM & Access Control Paradigm

- CX-0018 Dataspace Connectivity

- CX-0049 DID Document Schema

ESS incidents Data model

Note: For a top - down approach with IRS, an ESS incident does not have to exist in the form of the ESS Incident Data Model. The following parameters are sufficient for an ESS investigation:

- Catena-X ID of the product whose supply chain is to be investigated Industry Standard KIT

- BPNS (Business Partner Number Site) of the company under investigation Business Partner KIT

Nevertheless an investigation should be triggered only for an ESS incident occasion - related search.

List of all other standards used

The following standards were used in the creation of this Code of Conduct and serve as an additional source of information:

- ILO Code of Practice in Safety and Health

- ILO International Labor Standards

- ISO 14001

- OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas

- OECD Guidelines for Multinational Enterprises

- Universal Declaration of Human Rights

- United Nations Convention Against Corruption

- United Nations Convention on the Rights of the Child

- United Nations Convention on the Elimination of All Forms of Discrimination Against Women

- United Nations Global Compact

- High Conservation Value Resource Network (HCV)

- High Carbon Stock Approach (HCSA)

- Initiative for Responsible Mining Assurance (IRMA)

- Responsible Business Alliance (RBA)

- Drive Sustainability Guiding Principles

- Farm Animal Welfare Committee (FAWC)

- Terrestrial Animal Health Code

- Act on Corporate Due Diligence Obligations in Supply Chains

- Handreichung zur Umsetzung einer Risikoanalyse nach den Vorgaben des Lieferkettensorgfaltspflichtengesetzes (BAFA)